Electrical Safety

What is Electrical Safety?

Electrical safety is a general practice of workers who are exposed to handling and maintaining electrically powered equipment. It is a set of guidelines they follow to mitigate electrical hazards and prevent its dangerous effects in case of an incident. Unable to adhere to electrical safety can lead to accidents, near misses, or even fatalities.

Why Eliminate Electrical Hazards?

On the job site, working around electricity can be very safe when workers properly identify and control hazards. But, inadequate training, lack of experience and failure to recognize potential hazards could result in electric shock or death.

The construction industry is most at danger from electrical hazards, accounting for 52% of all electrical fatalities in the US workplace. Most of these incidents and fatalities were caused by direct worker contact with overhead power lines and contact with machines, tools, and hand-carried metallic objects. So how do we protect ourselves against these dangers?

Who is at Risk?

Engineers, electricians, and overhead line workers are at the top of the list of professionals who are most exposed to electrical hazards. Common tasks that put these workers at risk include electrical installation and repairs, testing of fixtures and equipment and inspection and maintenance activities. However, people who are indirectly working with electricity like office workers are also exposed to electrical hazards.

Electrical Hazards: Know Your Limits!

Electrocution is one of the most common hazards across construction sites according to OSHA. Identifying electrical hazards can help raise awareness of the risks, their severity, and how it can harm workers.

MAINTENANCE TIPS & CHECKLIST

IMPROVE ROI AND EXTEND EQUIPMENT LIFE WITH ONGOING MAINTENANCE PROCESSES

Heavy Machinery is the most expensive construction equipment you own. It’s also the costliest to repair or replace. This guide will show you how to save money and extend the life cycle of your equipment with regular maintenance best practices

WHY YOU NEED TO BE PROACTIVE ABOUT MACHINE MAINTENANCE

Being proactive in your heavy equipment maintenance schedule helps prevent expensive downtime. Regular maintenance helps predict when failure is likely to occur, allowing you to find a solution to problems before they happen.

COMMIT TO A PREVENTIVE MAINTENANCE PROGRAM

Preventive Maintenance (PM) helps anticipate change, and wear and tear. Corrective actions are taken continuously to ensure reliability and performance. PM involves regular systematic inspections, modification and replacement of components as well as performance testing and analysis.

A successful preventive maintenance program extends construction equipment life and minimizes unscheduled downtime caused by equipment breakdown. Benefits from a proper PM program include:

Improved equipment and system reliability

Reduction of unexpected breakdown

Decrease in expensive parts replacement

Extended equipment life

Improved resale value

Better parts inventory management

Preventive maintenance is more than regular maintenance like lubricating and changing and filters. A proper preventive maintenance (PM) program is all-inclusive. It’s an intentional approach to equipment management from the time equipment is purchased until the end of its useful life.

HOW TO BECOME AN ELECTRICAL ENGINEER: ELECTRICAL ENGINEERING DEGREES & CAREERS

Becoming an electrical engineer requires training, commitment, and the willingness to wonder about questions such as how a flat screen television manages to be energy efficient or how to use so much electricity without blowing a fuse.

Electrical engineers answer the tough electrical questions and may work on anything from handheld gadgets to massive electrical grids. In getting there, electrical engineers must consider questions such as: What level of degree should I get to maximize my income? What concentration should I learn to obtain my dream career? Do I have to join an engineering firm or can I work on my own?

This comprehensive guide is designed as a resource for individuals interested in the electrical engineering career path. Included are the steps to become a qualified electrical engineer, degree paths, potential salaries and projected career growth for specific subfields.

ELECTRICAL ENGINEERING CAREER BASICS

Electrical engineers use physics, electronics and electromagnetism to design devices that are powered by or produce electricity. Electrical engineers work on anything from small pocket devices to large aircraft electrical systems. Engineers test prototypes and evaluate and improve systems. Nearly every industry has a place for an electrical engineer, including government, transportation, communications, technology and utilities.

ELECTRICAL ENGINEERING IN-DEPTH

Electrical engineers are more than just system designers and developers. Engineers are involved in projects from conceptualization to maintenance. Engineers handle practicalities by conducting feasibility studies and cost analyses. Because of their multifaceted duties, electrical engineers sometimes specialize in project management, research and development or consultancy. Because of the wide range of industries using electrical engineers, many engineers specialize in sub-discipline of electrical engineering.

Electrical safety

Electricity can kill or severely injure people and cause damage to property. However, you can take simple precautions when working with or near electricity and electrical equipment to significantly reduce the risk of injury to you, your workers and others around you. This section provides a summary of those precautions.

What are the hazards?

The main hazards of working with electricity are:

electric shock and burns from contact with live parts

injury from exposure to arcing, fire from faulty electrical equipment or installations

explosion caused by unsuitable electrical apparatus or static electricity igniting flammable vapours or dusts, for example in a spray paint booth

What do I have to do?

You must ensure an assessment has been made of any electrical hazards, which covers:

who could be harmed by them

how the level of risk has been established

the precautions taken to control that risk

Maintenance

So far as is reasonably practicable , you must make sure that electrical equipment and installations are maintained to prevent danger.

Users of electrical equipment, including portable appliances, should carry out visual checks. Remove the equipment from use immediately and check it, repair it or replace it if:

the plug or connector is damaged

the cable has been repaired with tape, is not secure, or internal wires are visible etc

burn marks or stains are present (suggesting overheating)

How to Do Home Electrical Repairs

Your home’s plumbing and electrical systems may seem as different as any two things could be. But there are significant parallels. Water enters your home through a pipe under pressure, and, when you turn on a tap, the water flows at a certain rate (gallons per minute). Electricity enters your home through wires, also under pressure (called voltage, measured in volts). When you turn on an electrical device, the electricity flows at a certain rate (current, measured in amperes, or amps).

Unlike water, which is used as it comes from the tap, electricity is meant to do work: It is converted from energy to power, measured in watts. Since household electrical consumption is relatively high, the unit of measure most often used is the kilowatt, which is equal to 1,000 watts. The total amount of electrical energy you use in any period is measured in terms of kilowatt-hours (kwh).

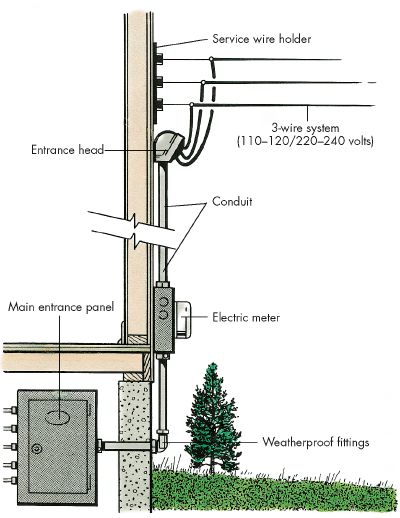

The instrument that records how much electricity you use is called an electric meter. This meter tells the power company how much electricity they need to charge you for. There are two types of electric meters in general use. One type displays a row of small dials on its face with individual indicators. Each meter dial registers the kilowatt-hours of electrical energy. For example, if you leave a 100-watt bulb burning for 10 hours, the meter will register 1 kilowatt-hour (10×100 = 1,000 watt-hours, or 1 kwh). Each dial registers a certain number of kilowatt-hours of electrical energy. From right to left on most meter faces, the far right is the one that counts individual kilowatt-hours from 1 to 10; the next one counts the electricity from 10 to 100 kilowatt-hours; the third dial counts up to 1,000; the fourth counts up to 10,000; and the dial at the extreme left counts kilowatt-hours up to 100,000. If the arrow on a dial is between two numbers, the lower number should always be read.

The second type of electric meter performs the same function, but, instead of having individual dials, it has numerals in slots on the meter face, much like an odometer in a car. This meter is read from left to right, and the numbers indicate total electrical consumption. Some meters also use a multiplying factor — the number that appears must be multiplied by ten, for instance, for a true figure in kilowatt-hours. Once you know how to read your meter, you can verify the charges on your electric bill and become a better watchdog of electrical energy consumption in your home.

Three main lines (older houses may have two) are responsible for supplying 110-120/220-240 volts AC (alternating current) to your home. The exact voltage varies depending on several external factors. This three-wire system provides you with 110-120-volt power for lighting, receptacles, and small appliances as well as 220-240-volt power for air conditioning, an electric range, a clothes dryer, a water heater, and, in some homes, electric heating.