Step by Step motorcycle engine rebuild

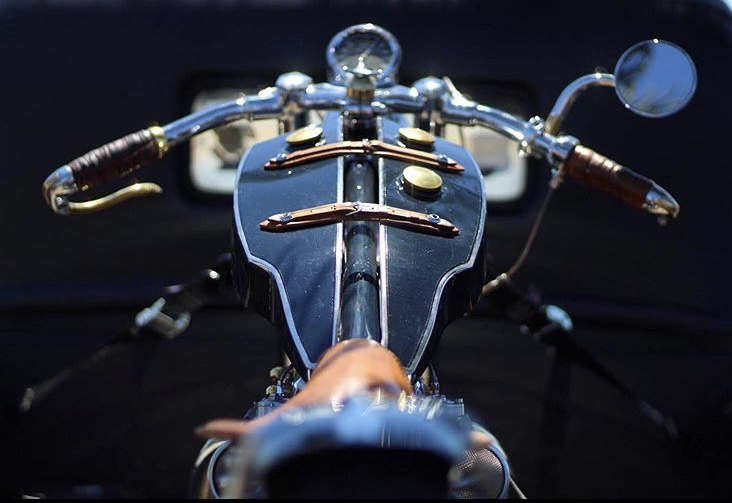

In our second installment for the Purpose Built Moto Guest Builder series, we linked up with Ian Don, a mate of mine for a while now who you may recognize from the custom builder documentary “Handcrafted“. Ian is Known for building technically brilliant and beautifully detailed vintage triumphs. Ian’s a self-taught man, with a lot of skills he could share. When I asked him to be part of the series, he jumped in headfirst and wanted to give you all an insight into an engine rebuild. Something he’s grown to love after getting to know the process and becoming comfortable in his skills with the rebuilding in’s and out’s.

This article take’s a high-level approach to showing you the steps you can take to tackle an engine rebuild your own motorcycle engine. written around a vintage triumph engine rebuild, however, the steps covered here can be logically applied to any motorcycle. the idea isn’t to hold your hand through the entire process but to give you enough information to inspire the confidence you need to go and learn the rest on your own. So let me shut up and hand you over.

“Many a time when I’ve been leaving an event or the local to have drawn a small crowd around the bike, there’s always a couple of old guys there quietly whispering about how it might be shiny but those old triumphs are a bugger to start “ten kicks at least”

It’s always really satisfying to tickle the carbs, whisper a quick warning to the bike under my breath “don’t you dare not start in front of all these people” and kick the bike into life with a single kick, try not to look too smug and take off giving the fuel tank a little pat.

For me when I decided to build my first engine a pre-unit 1951 Triumph I had never done anything more than changing the oil and filter on a car. I actually didn’t even know the names of the major components so I bought a Haynes manual and then just spent hours pouring over the diagrams and learning the part names and studying the diagrams so that I could actually get my head around how the engine worked and what parts did what.

ADVANTAGES & DISADVANTAGES OF REBUILDING YOUR ENGINE

So you or your mechanic has discovered the bad news: your vehicle or equipment needs a new engine. The next step hinges on two major factors: the age of the vehicle or equipment and your budget. Read on for a summary of how these factors affect your choice of a new engine or rebuilding the existing one. After that, bring yourself up to speed with our handy list of advantages and disadvantages of rebuilding an engine.

OLD ENGINE, NEW TRICKS

So what is a rebuilt engine exactly? Using extensive experience and precise tools, EngineTech’s staff cleans, hones, bores and rebuilds your engine from the ground up. The end product is essentially a brand new engine with enhanced performance and efficiency. A rebuilt engine often costs less than a new or used engine, let alone a new vehicle or piece of equipment. We back our rebuilt engines with warranty programs designed to keep your rebuilt engine running smooth.

IS IT WORTH IT?

As mentioned above, two main elements impact the value of rebuilding an engine.

How old is the vehicle or equipment that needs the engine?

If it is more than 10 years old/250,000 km, a rebuilt engine’s value may not live up to its cost. Old vehicles or equipment can suffer non-engine-related breakdowns and mechanical failures– leaving you with a working engine and nothing to make use of it.

What is your budget?

Another key issue when deciding between new and rebuilt is deciding what you can afford. New vehicles and equipment usually require down payments worth thousands of dollars. If not, you might also be at risk of overpaying in interest over the lifetime of your financing. Rebuilt engines are almost always more affordable– if you can afford the aforementioned down payment, you can likely pay for a rebuild outright (no future payments required).

The Difference Between Used, Rebuilt And Remanufactured Diesel Engines

Diesel engines are have long been used successfully in multiple industrial and commercial applications around the globe, due in part to their efficiency and long life span, and constitute the vast majority of units in service. Coupled with an electric generator, these gensets are valuable energy sources where there is no connection to a power grid or source of electric power. Remote applications in the energy, mining, marine and other industries often make generator sets a necessity

They are also a reliable source of emergency power as a reliable standby when the grid fails or is compromised. Their use in hospitals, commercial buildings, and first responder facilities has been well recorded for their reliability after natural disasters. When purchased new, their service life can be lengthy with proper operation, loading, and maintenance. They are readily available in the marketplace as used, providing useful life. Diesel engines and generators can be further extended by rebuilding or remanufacturing.

What Are Used Diesel Engines?

Used diesel engines are exactly that. They have had previous service with a prior owner or operator and, subject to testing, are deemed to be operational or can generally be repairable.Their minimum life span can be negotiated contractually with the seller based on a warranty.

Pros And Cons Of Used Diesel Engines

The purchase of a used diesel engine or genset is usually the least expensive option. The caveat is that there is no guarantee that the engine will perform as intended or for the necessary service life. Internal components of the engine are not disassembled, replaced and not normally inspected.

What Are Rebuilt Diesel Engines?

Rebuilt engines are ones that have been disassembled and inspected. Once the inspection process has been completed serviceable parts, as defined by manufacturer’s specifications, are reused.

SIGNS IT MIGHT BE TIME TO REBUILD YOUR DIRT BIKE ENGINE

When to rebuild your four-stroke dirt bike engine? This is a great question. First, we need to determine how to know when the right time comes to rebuild your four-stroke.

Engine wear is directly related to RPM and mechanical stress, so riders engaging in riding where the engine is on the rev limiter frequently, the engine is operating at a high RPM without any load on it, the gearbox is loaded or unloaded abruptly, or gears are selected hastily will require the rider or mechanic to service the engine frequently.

Most of you will relate the scenario I have illustrated to motocross racing. At the top levels of racing, mechanics are constantly checking or rebuilding the engines to make sure they are operating at maximum power.

Fortunately for most of us we are not riding or racing at the top level, so our bikes and engines last quite awhile longer. Unfortunately everyone’s scenario is different- depending on the type of riding you do, the environment you ride in, how often the oil is changed, etc. which makes it difficult to standardize or pinpoint any sort of service interval.

As an engineer, mechanic, and rider my philosophy has always been to replace components preventatively before they fail. My reasoning here is that the costs attributed with a failed component are much higher than a replaced component. Let us consider a scenario where a piston fails. This could have been avoided had I replaced the piston, which would have only cost me $130. Instead it’s quite likely that the entire engine will need to be opened up and serviced, making the price of the repair extremely expensive.

TIPS FOR TURBOCHARGED DIESEL ENGINE MAINTENANCE

Diesel technology has come a long way in recent years from ultra-low sulfur diesel to biodiesel. Gaining DPF filters to cut down on emissions and high efficient common rail injection systems to gain maximum miles per gallon. All of these changes are great if you are taking the proper steps to keeping your diesel vehicle running at peak performance. How do you do that you may ask, well luckily for you we are here to help.

Diesel Engine Turbochargers

Turbochargers are a huge part of making your diesel run efficiently. In order for you to get the maximum life and performance out of your induction system there are a few simple ways to make sure this part does not fail prematurely.

First off always allow your vehicle to start up and idle for a few minutes. Getting in and mashing the gas as soon as you start it is one of the worst things you can do to a cold engine. You must allow time for oil to reach all the nooks and crannies inside of your engine, the turbo is just one of the major parts this oil needs to reach.

Oil additives are also great for turbochargers and oil systems in diesel vehicles due to the amount of heat these engines create. Oil additives will help keep lubrication at peak levels and help these intricate parts stay running for a long time.

Biodiesel, ULSD & Diesel Fuel Additives

Fuel has been going between ULSD and biodiesel. These are the two main fuels you will see at any truck stop or fuel station. No matter what one is readily available near you a diesel fuel additive is always necessary. Diesel fuel additives will keep those injectors flowing at full capacity, with a nice even spray pattern.

You also want to find a fuel additive that demulsifies water. A lot of additives on the market will try and burn the water out through the injection system, but why? Why make it harder for your diesel vehicle that has a fuel water separator for a reason? The fuel water separator is made to take the water out of diesel fuel, so find yourself an additive that removes water and makes that systems job that much easier.

Another thing diesel fuel additives are great for is fuel gelling. In the cold months no one wants to go out to their vehicle for it not to start, so why not have a sense of security by using a fuel additive to eliminate this headache.